Automation

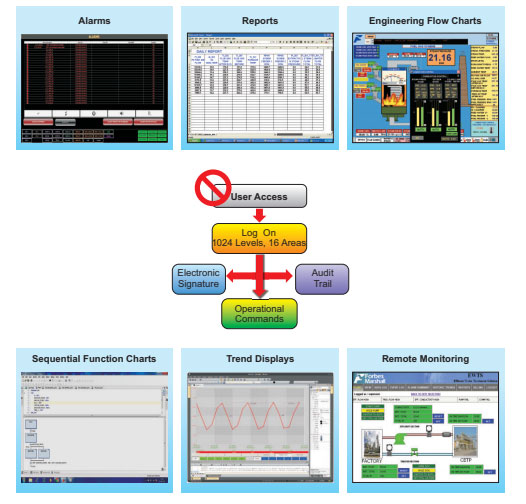

SCADA

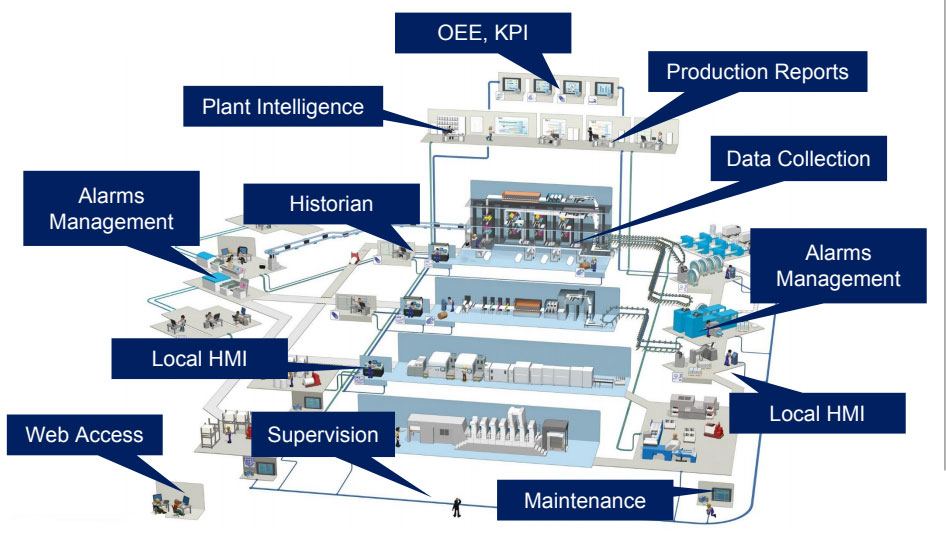

Plant Visualization Software in the Network

Mobile Access

PLC

Multifunction Panel

Operating Panels

Central Processing Unit

RTU

RTU Edge Device

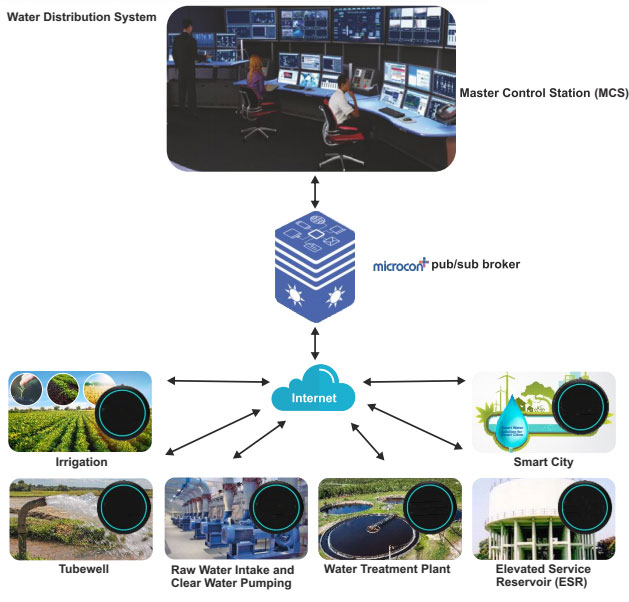

Event based secure protocol connects clients (producers and subscribers) to get live data (semi real-time) even on non-real-time connections. The dedicated protocol ensures optimal latency with lowest possible traffic even on mobile networks (also 2G) and Narrow Band Iot (NBIoT).

Microcon+ Pub/Sub Broker

The broker is the software that transfers data from devices into their digital twin in the internet/intranet. The broker collects and decodes live data, trades the interconnections between producers and consumers, scales the system, administers devices and users and initiates systems actions. The broker can run on premises for a few hundred connections or can run in a virtual data centre to represent millions of devices. It is currently the only broker which can be used in exactly the same manner on an edge cloud controller as well as in the cloud.

Microcon+Web Interface

In addition to providing the data to the SCADA system, the broker also provides a web interface. With this the users can perform administration of projects and programme basic functionalities like map, alarming, dashboards to the user. It provides a simple to use, cost efficient solution for IIoT with even a single device. It is also used to configure and upgrade all RTtru201 edge devices with detailed diagnostics like signal strength, IMEI number, etc., at a single place.

DCS